Quality Control Standards (QCS) ensure excellence in the delivery of products/services. With strong QCS, a company will remain competitive and grow its consumer base, and therefore develop a strong brand. The reason why many companies do not favor a complete implementation of robust QCS is because they could become costly and may require additional personnel. This goes back to the concept of cost-benefit analysis. For many companies, the cost is too great and usually the benefits are not easily quantifiable. Accordingly, the majority of companies settle with slim and inefficient QCS.

Here is the Best Process to use:

A. EFFICIENT SAMPLING:

In order to determine if the delivery of products/services is in accord to acceptable standards, an efficient sampling method is required. Larger companies that produce millions of widgets for example, cannot inspect every item individually. It is simply impossible for obvious reasons. As a result, a sampling method must be implemented with the primary function of representing the entire production/servicing output. There is a multitude of sampling methods used by companies and you should educate yourself on some of them. However, the sampling mechanisms that are the most effective are those that simply reduce strategically sampling errors.

Example:

Let’s assume that company manufactures CD players. As a sampling method, the Company decides that every tenth CD player will be inspected by a quality inspector located in a specific location along the assembly process. Let’s also assume that this sampling method is active at all times throughout the assembly process. Lastly, we will also assume that this inspection of the sample is the only quality control system in place. With this sampling method, the Company hopes to catch every deficiency in the production line. Can you envision some potential sampling errors?

Here is the answer:

This sampling method has a big problem. On the surface, it seems to possess an acceptable sampling method. However, it lacks randomness, which makes it ineffective. Let’s assume for example that the main production equipment is wrongly programmed and produces a faulty CD player every eighth copy. This means that the Company may never catch this error and possibly every customer who buys every eighth CD player produced will be calling the merchandise return department.

This sampling error could have been avoided using the following system for example:

- On Monday, every tenth copy will be inspected―On Tuesday, every ninth copy―On Wednesday, every eighth, and so on.

- Alternatively, the Company could have changed the sequence based on the time of the day.

- Or even, change randomly the formula every hour

The best strategy is to develop constant randomness, which will bear higher success of detecting potential production errors.

CORRECTION STRATEGY:

The Correction Strategy is the plan of action ready for activation in the event of the discovery of undesired standards. It is critical that this plan of action is well crafted and outlined in advance so as not to halt the production/servicing schedule. Therefore, when a snag is found, a plan is already in place to fix it.

Note:

An emergency brainstorming/strategy session is impractical during a moment of crisis because it leads to the implementation of unproved systems.

INCENTIVES:

An efficient QCS should always include an incentive system to encourage the participation of everyone in the organization. In many organizations, the top-level managers will rely only on the QCS they have implemented to catch every error in the production/servicing. It is without doubt a very bad approach. In addition to the company’s standards, the good managers will also seek to spur the critical thinking ability of each employee. These managers understand that their employees are an essential source in the improvement of quality. Consequently, they need to be incentivized to trigger their willingness to participate actively in the process. Monetary or promotion incentives are of course on top of the list. For example, a company may have as a policy to promote immediately an employee who finds significant errors in the production of products. Alternatively, the policy may be to reward employees with bonus payments if they develop strategies that would reduce production errors.

Other articles

DEVELOPING THE BEST FINANCIAL STRUCTURE

Get it sooner and you can invest it faster. The decision-making process is always easier if the top leadership is able to review swiftly the financial information of the company. For example, it should be unacceptable to wait weeks just to receive reports about the...

COMPENSATION ANALYSIS EXPLAINED

IMPORTANCE

The Compensation Analysis examines the financial burden and contribution of employees in an organization. Many decision makers tend to ignore the compensation analysis and it is to their detriment for long-term success.

PERFORMANCE MANAGEMENT EXPLAINED

IMPORTANCE

Performance Management measures the efficiency of the business and financial systems of a company. It also serves to enlighten possible areas of concern that may be detrimental to the organization’s smooth operation and financial profitability.

WHAT IS BUSINESS INTELLIGENCE (BI), AND HOW HELPFUL IS IT?

We live in a new Era We live in an era where speed and efficiency are the most desirable characteristics. The ability to obtain data, manipulate it, and develop actionable steps based on the information collected determines the secret to achieving these two factors....

GROWTH MANAGEMENT EXPLAINED

IMPORTANCE

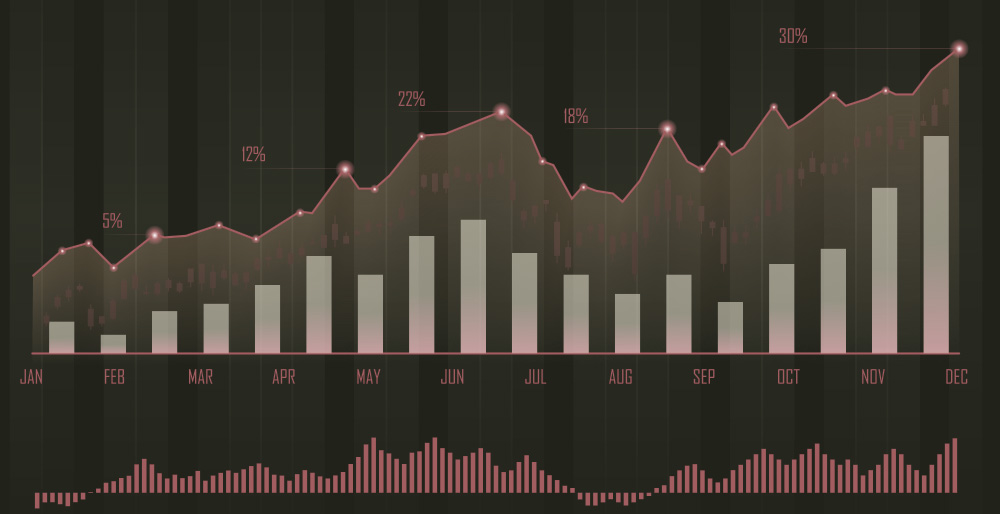

Growth Management is the process in place to ensure that the company’s market value increases on a consistent basis.

The following key tenets will ensure growth on a long-term basis:

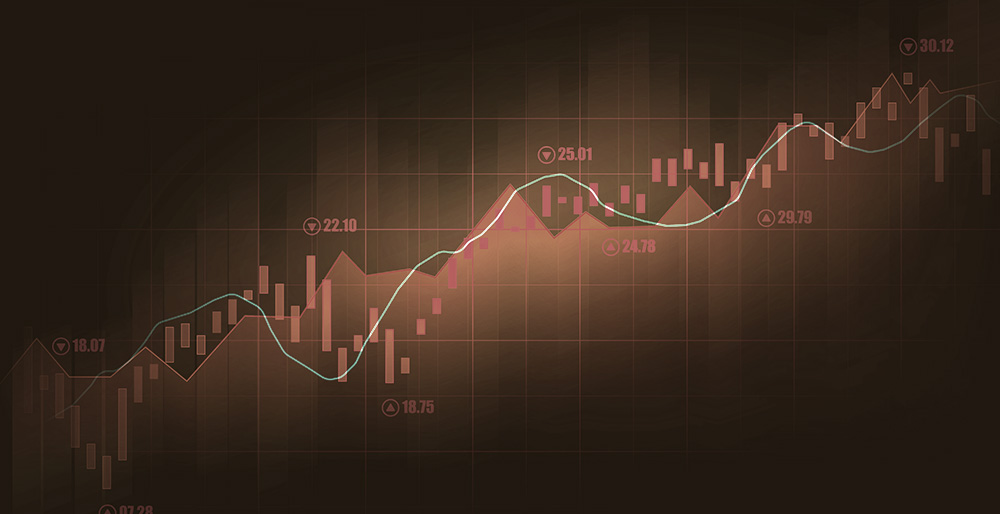

FINANCIAL ANALYSIS EXPLAINED

IMPORTANCE

The financial analysis enables the decision-maker to review the financial information of the company and make the best decisions. It should be unacceptable to manage any operation or project without fully understanding your financial position.